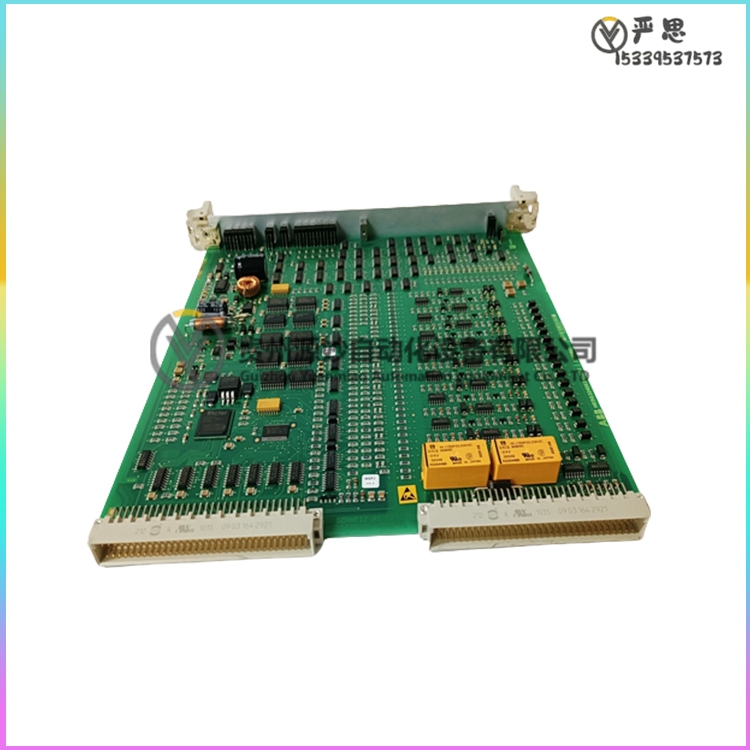

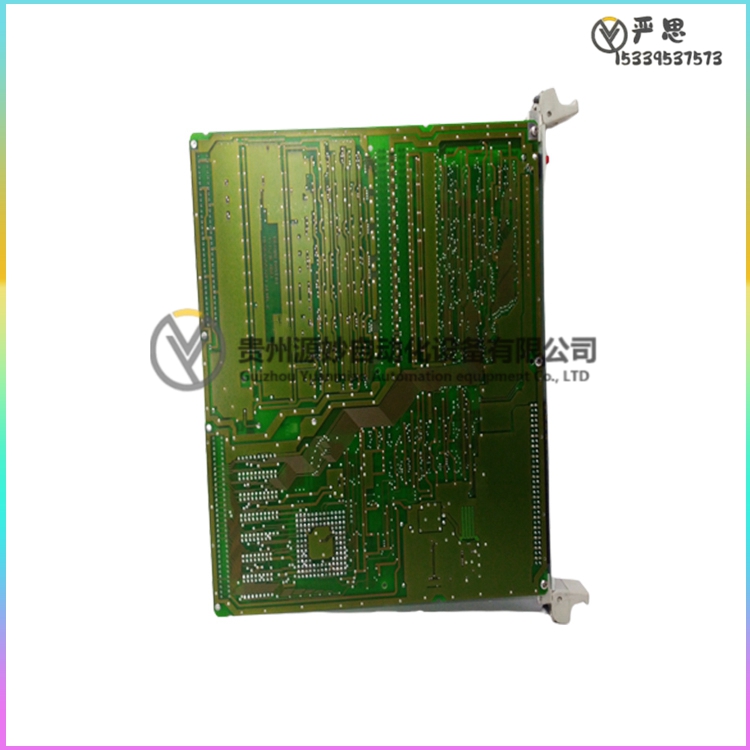

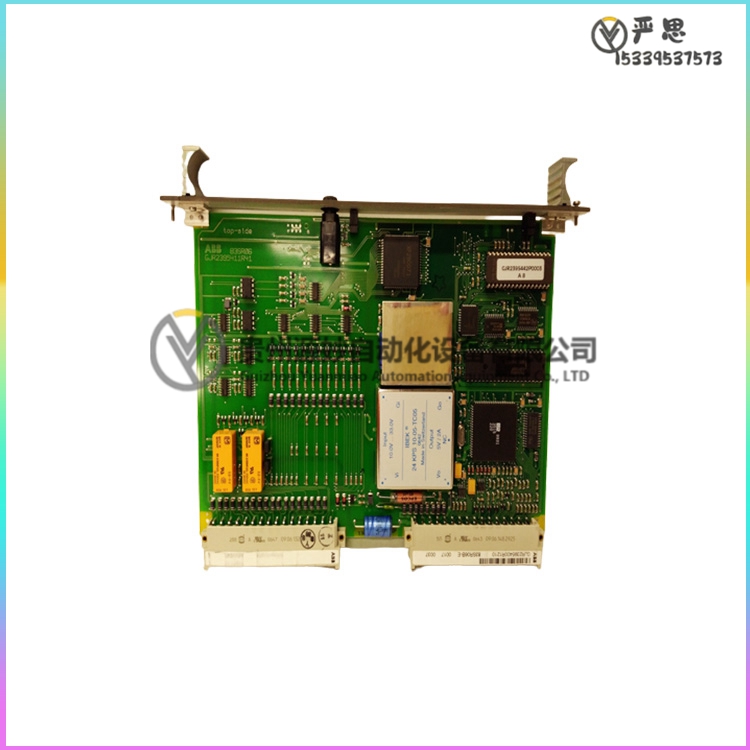

ABB PFEA112-65张力控制器是ABB公司推出的一款高性能张力控制设备。以下是关于这款张力控制器的详细介绍:

功能与应用:

该控制器专门用于控制和监测张力,特别是在卷材或带材的生产和加工过程中。它确保物料在生产或加工过程中保持恒定的张力,有助于提高生产过程的稳定性和产品质量。

广泛应用于印刷、涂层、拉伸、包装、纸张和纤维行业等各种工业应用。

技术特点:

高精度测量:采用高精度的传感器技术,能够实时准确地测量材料的张力值。

多种接口:支持多种通信接口,如RS232、RS485、以太网等,方便与其他的控制系统或上位机进行数据交换和控制。

用户友好:提供简单易用的人机界面,支持多种语言,方便用户设置参数、查看实时数据和历史数据。

灵活性高:支持多种不同的控制模式,如手动控制、自动控制等,可以根据实际需求进行选择和配置。

易于集成:支持多种工业自动化协议,如OPC、Modbus等,方便与其他工业自动化设备进行集成和控制。

传感器与反馈系统:

通常使用张力传感器或加载细胞来检测卷材或带材的张力,并将反馈信息发送给控制系统。

控制系统根据反馈信号实时调整驱动设备的速度或力,以确保张力恒定。

自动化程度:

该控制器具有高度自动化程度,能够自动调整设备以维持所需的力水平。

如果发现力量不足或过大,该装置会进行相应的调节,以保证产品质量稳定性。

提供实时数据反馈给操作员,以便于对生产线运行状态做出及时反应并优化工艺参数设置。

总的来说,ABB PFEA112-65张力控制器是一款功能强大、易于使用的张力控制设备,能够有效提高生产效率并降低成本风险。

The ABB PFEA112-65 Tension controller is a high-performance tension control device from ABB. The following is a detailed description of this tension controller:

Functions and Applications:

The controller is specifically designed to control and monitor tension, especially during the production and processing of coils or strips. It ensures that the material maintains a constant tension during production or processing, helping to improve the stability of the production process and product quality.

It is widely used in various industrial applications such as printing, coating, stretching, packaging, paper and fiber industries.

Technical features:

High-precision measurement: Using high-precision sensor technology, the tension value of the material can be accurately measured in real time.

Multiple interfaces: Support a variety of communication interfaces, such as RS232, RS485, Ethernet, etc., to facilitate data exchange and control with other control systems or host computers.

User-friendly: Provides an easy-to-use human-machine interface, supports multiple languages, and is convenient for users to set parameters, view real-time data and historical data.

High flexibility: supports a variety of different control modes, such as manual control, automatic control, etc., can be selected and configured according to actual needs.

Easy integration: Support a variety of industrial automation protocols, such as OPC, Modbus, etc., easy to integrate and control with other industrial automation equipment.

Sensors and feedback systems:

Tension sensors or loading cells are usually used to detect the tension of the coil or strip and send feedback to the control system.

The control system adjusts the speed or force of the driving device in real time according to the feedback signal to ensure that the tension is constant.

Degree of automation:

The controller has a high degree of automation and automatically adjusts the equipment to maintain the required force level.

If the force is found to be insufficient or too large, the device will be adjusted accordingly to ensure the stability of product quality.

Provide real-time data feedback to the operator to make timely reactions to the operating status of the line and optimize process parameter Settings.

Overall, the ABB PFEA112-65 tension controller is a powerful, easy-to-use tension control device that can effectively improve production efficiency and reduce cost risk.

【免责声明】

贵州源妙自动化设备有限公司我们销售新产品和停产产品,独立渠道购买此类特色产品。贵州源妙自动化设备有限公司不是本网站特色产品的授权分销商、经销商或代表。本网站上使用的所有产品名称/产品图片、商标、品牌和徽标均为其各自所有者的财产。带有这些名称,图片、商标,品牌和徽标的产品描述,描写或销售仅用于识别目的,并不表示与任何权利持有人有任何关联或授权。

客服1

客服1