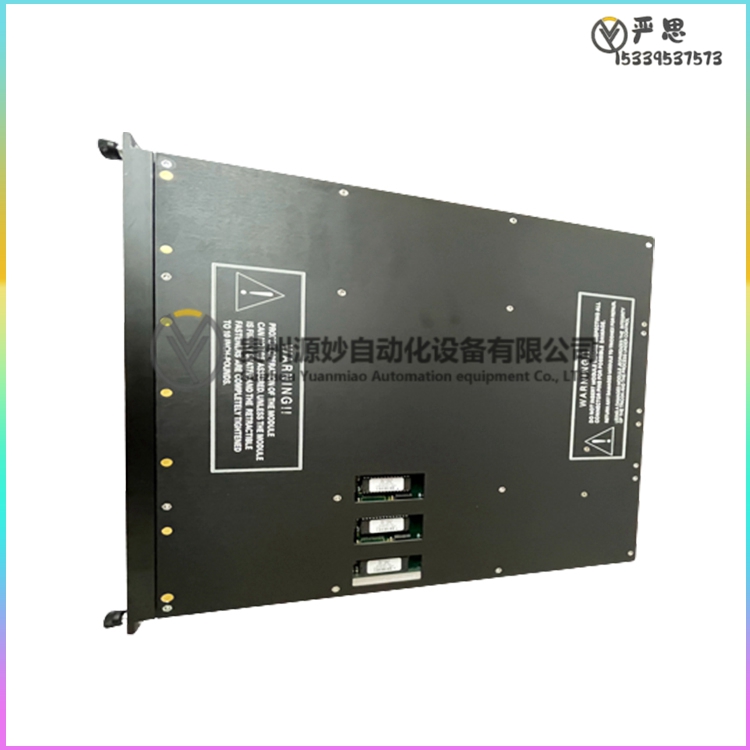

TRICONEX 3451是一款在工业控制领域中广泛应用的先进远程终端单元和安全仪表系统,具有高度的可靠性、安全性和高效性。

作为一款远程终端单元,TRICONEX 3451在PLC(可编程逻辑控制器)的基础上进行了升级和扩展。它遵循特定的梯形逻辑编程,无需用户干预或来自更智能的控制器或主控制器的输入,就能控制多个过程。这使得TRICONEX 3451在工业自动化系统中扮演着关键的角色,通过向分布式控制系统(DCS)和监控与数据采集(SCADA)系统发送遥测数据,实现了与这些系统的无缝连接。

同时,TRICONEX 3451还是一款安全仪表系统(SIS),为工业过程提供关键保护。它采用了三模冗余(TMR)架构,确保了系统的高可靠性和稳定性。即使在单一组件故障的情况下,TRICONEX 3451仍能维持系统的正常运行,从而保证了工业过程的安全性和连续性。此外,它还具备高速加工、先进的诊断以及直观的用户界面等特性,使得操作和维护变得更加简单和便捷。

在工业物联网架构中,TRICONEX 3451也扮演着重要的角色。它连接了生产资产和云,实现了生产和流程资产(OT)与边缘和云层(IT)之间的所需连接和信息转换。这种转换使得不同系统之间的通信和协作成为可能,提高了整个工业系统的效率和可靠性。

TRICONEX 3451还具有广泛的应用领域,包括石油和天然气、化学处理、发电、水和废水处理等。在这些领域中,TRICONEX 3451能够监测和控制各种参数,确保生产过程的稳定性和安全性。

The TRICONEX 3451 is an advanced remote terminal unit and safety instrumentation system for industrial control applications with a high degree of reliability, safety and efficiency.

As a remote terminal unit, the TRICONEX 3451 has been upgraded and extended based on a PLC (Programmable logic Controller). It follows a specific ladder logic programming to control multiple processes without user intervention or input from a more intelligent controller or host controller. This makes the TRICONEX 3451 a key player in industrial automation systems, seamlessly connecting with distributed control systems (DCS) and supervisory Control and Data acquisition (SCADA) systems by sending telemetry data to them.

The TRICONEX 3451 is also a Safety instrumentation system (SIS) that provides critical protection for industrial processes. It adopts three-mode redundancy (TMR) architecture to ensure the high reliability and stability of the system. The TRICONEX 3451 maintains system operation even in the event of a single component failure, ensuring the safety and continuity of industrial processes. In addition, it features high-speed machining, advanced diagnostics and an intuitive user interface, making operation and maintenance easier and more convenient.

In the industrial iot architecture, the TRICONEX 3451 also plays an important role. IT connects production assets and the cloud, enabling the required connectivity and information transformation between production and process assets (OT) and edge and cloud (IT). This transformation enables communication and collaboration between different systems, improving the efficiency and reliability of the entire industrial system.

The TRICONEX 3451 also has a wide range of applications, including oil and gas, chemical treatment, power generation, water and wastewater treatment, and more. In these areas, the TRICONEX 3451 enables precise monitoring and control of various parameters to ensure the stability and safety of the production process.

【免责声明】

贵州源妙自动化设备有限公司我们销售新产品和停产产品,独立渠道购买此类特色产品。贵州源妙自动化设备有限公司不是本网站特色产品的授权分销商、经销商或代表。本网站上使用的所有产品名称/产品图片、商标、品牌和徽标均为其各自所有者的财产。带有这些名称,图片、商标,品牌和徽标的产品描述,描写或销售仅用于识别目的,并不表示与任何权利持有人有任何关联或授权。

客服1

客服1